Meet HERCULES

Meet HERCULES

The Industrial Fryer that Heats Hard Where It Matters Most

You know how the first electric cars were just retrofitted gas

cars? Awkward, inefficient, uninspired. It took a ground-up

redesign to make electric work — and now look where we are.

That’s the idea behind HERCULES:

Not just a fryer with a micron filter bolted on. But a from scratch

system built for the biggest, fastest, most demanding

convenience food lines in the world — and optimized to make

your product shine while making your oil last.

Golden Brown Perfection – That’s Where It All Starts

Let’s be real: Nobody buys a fryer because it’s good at cleaning.

You buy it because you want crispy, golden, perfect products — every single time.

HERCULES brings the heat (literally and figuratively):

- Continuous oil circulation across the entire fryer length

- A gentle-flow deflector keeps products from sticking together as they land

- At the entry, an extra burst of thermal oil compensates for cold load — like ice-cold INSTAMIX Tempura nuggets, we shock them continuously

- Result: instant crusting, sealed moisture, and coatings that crunch like a dream

![]() Crisp on the outside, juicy on the inside — and all of it repeatable.

Crisp on the outside, juicy on the inside — and all of it repeatable.

Triple Heat Zone Mastery

2 or 3 individually controlled thermal oil zones means:

- You fry smart — adjusting for setting, crusting, and finishing

- You reduce product sticking or tearing

- And when production pauses? HERCULES knows it minutes in advance

That’s right — WIZZ Connect anticipates a stop and already shuts off zone 1 heating before the

last cold product enters, avoiding unnecessary overheating.

Your line paused? No worries — HERCULES already saw it coming

and turned down the heat. Frankly, it’s like it read the production

manager’s mind (but with fewer meetings).

320 L/min Micron-Pro Filtration

Filter Like You Mean It

The paperless Micron-Pro system filters up to 320 liters per minute without pausing production.

It captures even fine flour or batter dust, keeping the oil in top shape.![]() Cleaner oil = better taste, better yield, longer life

Cleaner oil = better taste, better yield, longer life![]() Filter the entire fryer volume every few minutes

Filter the entire fryer volume every few minutes![]() And zero paper waste, because that belongs in the past

And zero paper waste, because that belongs in the past

Hercules Debris Handling — The Part Everyone Knows,

Fixed by Design

Every Fryer Has That Trolley. Hercules Doesn’t.

Anyone who has worked around large fryers knows the routine:

- Two or three debris take-off points. Bottom screws doing their job. An inclined conveyor climbing up… and then dumping hot crumbs mixed with oil into an open 200-liter trolley.

- That trolley gets watched.

- Extra fire protection gets added.

- And at some point, someone says: “Keep an eye on that one.”

![]() On the Hercules fryer, that familiar weak point simply doesn’t exist.

On the Hercules fryer, that familiar weak point simply doesn’t exist.

Hercules integrates Micron filtration as part of the fryer design, not as a separate system. Debris is removed through closed piping and pumped directly to the Micron-Pro unit, where it is under high pressure de-oiled to just 0.5–1.5% residual oil before discharge.

No exposed conveyors.

No oil-soaked crumb wagons.

And no nervous looks at the debris conveyor and trolley — because they’re not there.

→ Closed, integrated debris removal by design

→ Light floating debris like angel hair also taken out

→ Dry crumbs instead of oil-laden waste

→ Lower fire risk without additional suppression hardware

→ Cleaner handling, less oil loss, less stress on the line

Same frying reality.

One less thing to worry about.

That’s Hercules.

Smart TPM Monitoring — Finally Real-Time, Finally Practical

We made TPM testing operator-proof and fully trackable:

- A red light triggers a measurement

- The peek sample tube reaches the actual oil flow level

- An operator uses the Hercules handheld TPM meter with clean tip

- Result is logged in WIZZ Connect with date, time, oil temperature & TPM level

Now that’s real oil management. Not guessing. Not post-shift. Not when it’s already too late.

Smart Oil Recovery & Sustainable Cooldown – Clean Oil, Clean Conscience

Cool Down Like a Pro

At shift’s end, most fryers just… sit there. HERCULES performs a smart cooldown routine:

- Fresh, cool oil is added and circulated

- Temperature gradually steps down

- System drains till above the heat exchanger passing through the Micron before returning to the overnight tank

- Cycle repeats itself till a safe ca. 140 C temperature is reached (ca 20 minutes)

- No thermal oil contamination, no metal fatigue

→ Your fryer ages like fine wine.

At end of cool down, HERCULES flips the script:

- All oil is pumped into the insulated double wall, closed overnight tank, fully filtered

- A slow-turning U-shaped steerer rotates the oil along the tank walls

→ This accelerates cooling to below 80 °C — the critical point before TPM starts rising

![]() sustainability genius:

sustainability genius:

The still-hot/warm oil tank preheats incoming cold cleaning water, which then flows into the

fryer. We cool the oil and heat the water through the spiral water piping around the inner oil

storage tank

![]() Prevents thermal shock

Prevents thermal shock![]() Protects welds & metal

Protects welds & metal![]() Reuses residual energy

Reuses residual energy![]() Reduces oil oxidation

Reduces oil oxidation![]() Makes sustainability auditors smile wide

Makes sustainability auditors smile wide

Clean Like a Pro — With Zero Elbow Grease

HERCULES CIP system is no joke:

- 360° high-pressure spray nozzles

- 8 bar integrated cleaning of filters and fryer hood

- Electropolished surfaces for easy wipe-down

- Orbital-welded hygienic piping

No excuses, no shortcuts — just a clean fryer that stays clean.

Safety System That Reacts Before You Do

If something does go wrong, HERCULES doesn’t panic — it extinguishes.

- Fully automatic foam-based fire suppression

- Cooldown to safe temp in under 90 seconds

- Hood open? Fire is suppressed anyway

- Certified by TÜV and VdS

- Installed & maintained by professionals, not wishful thinking

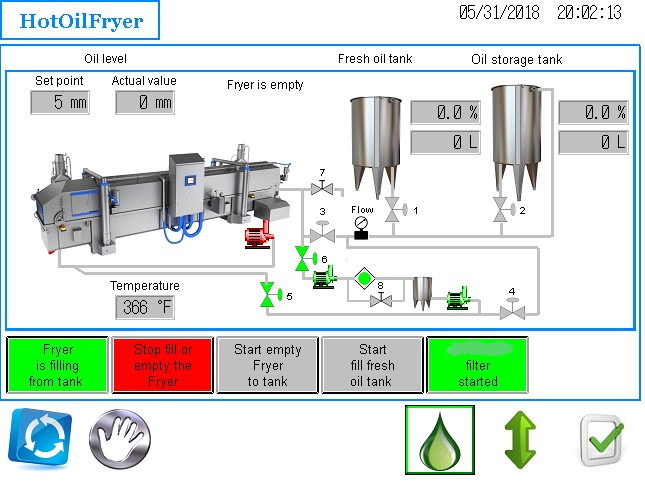

WIZZ CONNECT: Industrial Intelligence at Your Fingertips

The digital brain behind Hercules:

- Batch logs, TPM values, oil volume & oil usage per minute during production

- Combines batter/tempura viscosity data with live oil consumption

- Full visibility into motor loads, energy draw, and micron filter cycles

- One-touch control over oil routing, cooling, heating, and cleaning

- Emergency stops shut down the line upstream to protect the fryer

- And yes, your HMI stations are right where they need to be

Everything logged, everything traceable — and finally, usable.

✅ Bottom Line Benefits

✔ Lower operating costs

✔ Healthier frying, less oil ending up in human bodies

✔ Higher yield

✔ Longer oil life

✔ Safer operation

✔ Better product consistency

✔ Easier cleaning

✔ Auditable sustainability

✔ Full process visibility

Built for the Next Generation of Coatings

Especially INSTAMIX Tempura

Whether you’re frying battered shrimp, nuggets, vegan sticks, or southern-style bites —

HERCULES is your best friend if you care about:

- Crunch

- Color

- Clean oil

- Cost-per-kilo

- Coating recipe tweaking to optimize oil pickup

Pair it with INSTAMIX Tempura and you’ve got the gold standard, a fryer that warns when Tempura takes out more oil all of a sudden.

HERCULES Industrial Fryer – Key Dimensions & Technical Features

Whether you’re planning layout, installation, or just evaluating how this beast fits into your process — here’s what you need to know:

Product & Belt Handling

- Product height capacity: Up to 100 mm – ideal for nuggets, schnitzels, tempura prawns, and larger items

- Belt width (overall): 650 mm or 1050 mm

- Effective frying width (usable): 600 mm – 1000 mm designed to allow full-width product loading without edge loss

- Belt type: Stainless steel wire belt, 2.8 mm wire thickness – tough, food-safe, and optimized for frying

Frying System & Heating

- Usable frying length: 9.000 mm – 12.000 mm plenty of space for precision heat control and full crust development

- Belt width: 650 mm -750 mm - 1050 mm

- Adjustable frying time: 20 to 240 seconds – fully variable via frequency-controlled drive

(Other timings available on request) - Heating method: Thermal oil electro polished heat exchanger

◦ Power: approx. 72 - 120 kW per meter frying length

◦ Inlet temperature: 280 °C

◦ Return temperature: 260 °C - Oil volume (max): 2,900 liters depending fryer width – allows for stable temperature and long oil life

Machine Dimensions

- Total fryer length (incl. piping/housing): approx. 9.000-12,000 mm

- Total width at widest points (hood/chimneys): approx. 1,950 mm

- Infeed & outfeed height: approx. 980 mm, adjustable ± 50 mm

→ Makes line integration simple with upstream and downstream machines

Electrical & Exhaust

- Total connected electrical load: approx. 5.5 kW – energy efficient for a machine of this scale

- Electrical cabinet: Hygienic design, stainless steel, IP-rated for washdown environments

- Power supply: 400 V / 3-phase / 50–60 Hz

- Exhaust chimneys:

◦ Diameter: 250 mm each

◦ One exhaust fan per chimney, supplied by the customer

Additional Integration Highlights

- Compatible with all standard coating, frying, cooking, and freezing lines

- Ideal for high-throughput, continuous production environments

- Fully CIP-ready, easy to clean, and audit-friendly

- Oil management systems (e.g. filtration, cooling, tank transfer) are seamlessly integrated

The Final Word

It’s a fully-automated, sensor-rich, TPM-tracking, filter-integrated, triple-zoned, CIP-powered beast — disguised as stainless steel.

Ready to lift your line’s performance like Hercules lifted the world?

Let’s fry.

HERCULES + WIZZCONNECT = golden combination