Finding a better way to hit the ground running — every single start-up

Everyone’s talking about Full Self-Driving.

- Cars that remember.

- Cars that synchronize.

- Cars that don’t make you start from zero every morning.

So here’s the honest question:

Why are coating and frying lines still driving like it’s 1998?

Every start-up, we’re back behind the wheel.

Hands on every knob.

Eyes everywhere.

“Feels about right.”

That’s not driving.

That’s surviving.

WizzConnect is the FSD for coating and frying lines.

Not autonomous.

Not magical.

But:

- the line remembers

- the line synchronizes itself

- the line behaves the same way every time

One recipe restores the entire line.

Speeds aligned.

Settings exactly where they were.

One emergency stop. One disciplined restart.

- No rebuilding.

- No guessing.

- No “who touched what?”

So performance doesn’t depend on

* who’s on shift,

* who cleaned last night,

* or who needs coffee.

The comparison below shows the difference.

Once you’ve driven with FSD, going back feels painful.

Same thing here:

WITH WIZZCONNECT vs WITHOUT WIZZCONNECT

The difference between managing machines — and running a line with FSD installed

* MORNING START-UP

| Without WizzConnect | With WizzConnect |

| Each machine adjusted separately | One recipe loads the entire line |

| Belt speeds matched by eye | All speeds synchronized automatically |

| “Let’s see how it behaves today” | “This is exactly how it ran last time” |

| 30–60 minutes to reach stability | Line runs stable from the start |

| Stress before coffee | Calm start, every day |

Winner: With WizzConnect ☑

* PRODUCT CHANGEOVER

| Without WizzConnect | With WizzConnect |

| Operators rebuild settings | Line remembers previous runs |

| Repeating the same adjustments | One click restores all settings |

| Inconsistent results shift to shift | Identical setup every time |

| Tribal knowledge required | Recipe discipline |

| Time lost, every change | Time saved, every change |

Aha moment: The line has memory now.

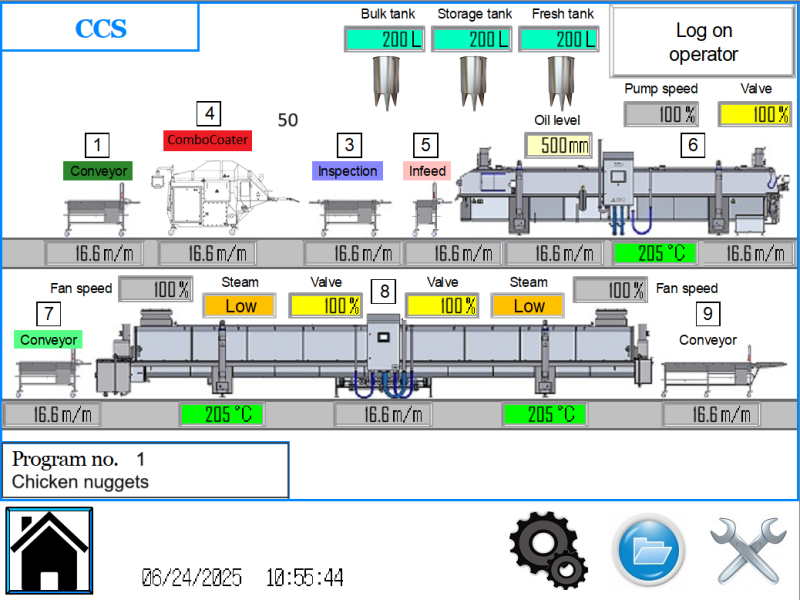

* LINE CONTROL

| Without WizzConnect | With WizzConnect |

| Machines/conveyors operate individually | Line behaves as one machine |

| Multiple local HMIs or water sensitive buttons | One central HMI wall or pilar mount |

| Operators walk the line | Operators see the whole line |

| Guesswork between machines | Full synchronization |

This is the moment people say: “Ah… now I understand.”

* TOUCHSCREENS & HYGIENE

| Without WizzConnect | With WizzConnect |

| Touchscreens on machines | No screens on machines |

| Vulnerable to high-pressure cleaning | Protected central HMI |

| Frequent damage & downtime | Lower maintenance, longer lifetime |

| Hygiene compromises | Cleaner, simpler design |

Simple change. Huge impact.

* SAFETY & EMERGENCY STOPS

| Without WizzConnect | With WizzConnect |

| Emergency stop stops one machine | Any E-stop stops the whole line |

| Operators running from machine to machine on wet floor | Calmly slam the first closest e-stop |

| Partial stops cause pile-ups | Clean, controlled full stop |

| Fryer continues to heat and overshoots | Thermal oil valve closes connected to e-stop |

| Restart chaos | Disciplined restart |

| Higher product risk | Higher safety & product protection |

This alone sells the system in many plants.

* DATA, LOGGING & FACTS:

| Without WizzConnect | With WizzConnect |

| Limited or local data | Full line data |

| No motor amp visibility | Motor amps continuously monitored |

| Faults disappear | Faults logged & timestamped |

| “I think it was…” | “Here’s exactly what happened” |

Facts beat opinions. Always.

* SCADA & COMPLIANCE:

| Without WizzConnect | With WizzConnect |

| Isolated machines | SCADA-compliant line supervision |

| Limited traceability | Full audit trail |

| QA reacts after issues | QA sees issues early |

| Paper & screenshots | Structured data |

Auditors love this. Managers sleep better.

* REMOTE VISIBILITY:

* REMOTE VISIBILITY:

| Without WizzConnect | With WizzConnect |

| You must be on the floor | View the line remotely |

| Management guesses | Management sees |

| QA waits for reports | QA checks live |

| Decisions delayed | Decisions made faster |

Clarity without boots and earplugs.

* WHAT THIS REALLY MEANS:

Without WizzConnect:

You manage machines and hope the line behaves.

With WizzConnect:

You run a line that behaves — predictably, repeatably, calmly.

- Operators are happier.

- Managers have facts.

- Food is treated with more discipline.

And consumers never notice the system —

they just enjoy better food.

** SUMMARY:

WizzConnect turns a collection of machines into one synchronized, documented, remotely visible coating line.