Introducing:

________________________________________________________________________________

The 1 Big Beautiful Bag Act

A revolutionary step for dust-free, operator-friendly, bulk powder handling.

Welcome to the Big Beautiful Bag System — our European parody-inspired (but deadly serious) innovation to help you say goodbye to dust clouds, strained backs, and mountains of packaging waste.

What Are You Doing Now?

Many tempura or batter mix users still operate the Old Inefficient Way™:

Lifting 50-pound bags 40 x per pallet is not a quality strategy

Oww that HURTS!!

That guy lifting bags?

He’s not “building character.”

He’s building a chiropractor’s summer house.

- 20 or 25 kg bags

- 40 per pallet

- Each bag manually lifted to hopper height?

- Or emptied in a trolley first then hopper topped up with a bucket?

- Every bag cut, shaken, wrestled open

- Cloud of floury dust covers operators and line sensors

- Costs extra per kg — and your sustainability score takes a hit

People in pain don’t have time to care.

People who rush don’t notice details.

And details are exactly where food quality lives!

A Small Philosophy Break (Bear With Us)

Happy chickens lay better eggs.

Stressed chickens lay… well… industrial eggs.

Fruit trees that are cared for produce healthier fruit.

Corn grown in exhausted soil tastes like disappointment.

And convenience/protein line operators? They’re no different.

If your operators spend every hour:

- lifting 25 kg bags,

- ripping them open,

- breathing dust,

- racing the clock,

then don’t expect artisanal care at the coating line.

What ends up on the consumer’s plate always reflects how it was made — and how the people making it were treated.

Enter the new 2026 Era where robots can take the shape of a human, a 4 wheeler with FSD, PICK&PLACE or:

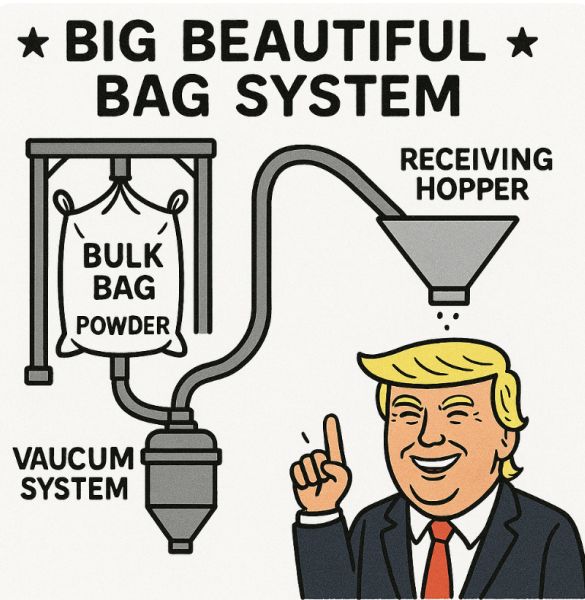

The Big Beautiful Bag System

Just like that one “big beautiful bill” we’ve heard so much about, this new system brings sweeping reform — but with fewer budget cuts and more hygiene.

- Big Bags of 500–1000 kg Tempura or batter mix

- Delivered in a hygienic, sealed format

- Hung once, no manual lifting

- Fully enclosed, dust-free emptying

- Pneumatic conveying straight to hopper — even at 3m height

- FSM enabled (Full Self Mixing) with Symotab Instamix

- Cut costs, save labor, keep operators clean and happy

What Would The Donald Say?

“We’re going to have the best bags. The biggest bags. Auditors are going to look at your factory and say: ‘Wow, those are some beautiful bags.’”

Is this comparison in anyway false:

| Feature | 25 kg Bag System | Big Beautiful Bag System |

| Packaging cost per lb | High - 40 bags per pallet | Low - bulk format, minimal waste |

| Labor per 450 kg | ~18 bags 18 lifts/shakes/hr | 1 bag hung, automated discharge |

| Dust & cleanup | High (operators + sensors) | Minimal (sealed system) |

| Waste & recycling | 40 bags/pallet discarded | 1 big bag only |

| Estimated cost per lb | $ X.XX baseline | 5-8% savings |

Fake News? Mail your truth to [email protected]

Cost Comparison Summary (per 1000 kg of powder)

| Cost Category | 50 lb Bags | 2,000 lb Big Bag | Why It Matters |

| Packaging | $0.05 / lb → $100 | $0.01 / lb → $20 | 40 small bags vs 1 big bag |

| Labor | $120 | $25 | 40 manual lifts vs 1 controlled hang |

| Storage space | $45 | $12 | Fewer pallets, better warehouse use |

| Transport | $70 | $35 | Higher payload per shipment |

| Waste Handling | $35 | $6 | One bag beats forty |

| Total operational cost | $370/ton | ≈ $100 / ton | ~70% reduction |

Why This Will Work in Your Factory Too:

- Manual labor is always a bottleneck. If your operators spend more time lifting than mixing or maintaining, you’re losing efficiency.

- Storage space is money. If your warehouse is tight, reducing pallet usage frees up room for raw materials or finished goods.

- Waste costs are increasing. Disposal and recycling are both rising in cost — one bag is always cheaper than 40.

- Food safety and hygiene are easier to maintain with a closed system. Fewer airborne particles = fewer complaints and cleaner equipment.

- Supplier leverage. Bulk format ordering shows volume commitment, often unlocking better terms or priority treatment

Care In = Quality Out

Happy chickens lay better eggs.

Crops grown with care taste better.

Grapes with more sunshine make better wine

Your Convenience/protein line managers determine the quality of your plants products.

Would doing away with bag or bucket lifting give them more time to optimize quality?

About POTEM

No ballots. No speeches.

If you want to know whether the Big Beautiful Bag System fits your coating line,

email the POTEM:

[email protected]

(President Of Tempura — self-appointed, fully operational)